Some products are intended for human consumption in the trucking sector. These products include food, pharmaceuticals, and other commodities. Transporting this cargo can be delicate and requires specialized trailers to protect it from any possible contamination. It is why there are trucks made for that purpose. One of these is the food-grade dry van trailer.

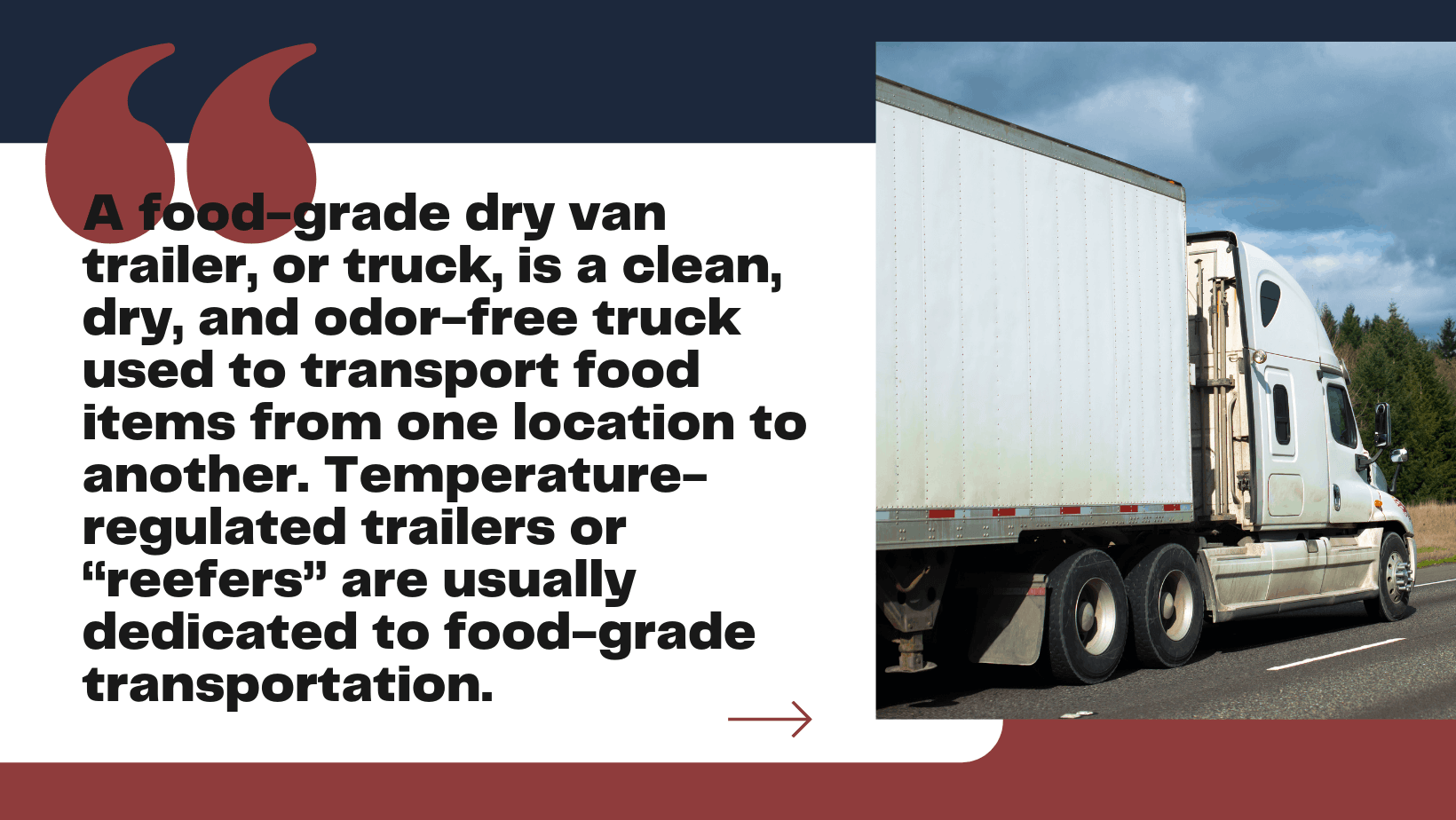

A food-grade dry van trailer, or truck, is a clean, dry, and odor-free truck used to transport food items from one location to another. Temperature-regulated trailers or “reefers” are usually dedicated to food-grade transportation.

Any trailer that can haul food items can be a food-grade dry van trailer as long as it meets strict conditions.

How Does a Standard Dry Van Trailer Differ From a Food-Grade Dry Van?

The difference between a standard dry van trailer and food-grade dry van comes down to cleanliness requirements. Since this van is designed to carry food items from milk to pasta, it carries sanitary requirements and other specifications to keep everything efficient.

Different food items can be transported in a food-grade dry van trailer, including powdered milk, coffee, cereal, rice, pasta, granulated sugar, tea bag, pet food, canned stew, canned fruit juices and many more.

Foods like vegetables, seafood, and dairy products can’t be transported in a regular food-grade dry van trailer.

These foods are perishable, so they need to be transported in a temperature-regulated truck, so they are delivered fresh and ready for the public’s consumption.

RT vamp_kris2102 "Volvo 630 (2005) #delivery #power #speed https://t.co/3yXwHUSQER Selling my volvo 630 with 53’ wabash food grade dry van with aluminum roof heated power mirrors pic.twitter.com/eNOmNlPPvC"

— Foma Seebe (@eligeSeebe) April 30, 2020

What Determines a Food Grade Trailer?

A standard food-grade dry van trailer has specific features. These features are what differentiates it from a conventional dry van trailer. Here are a few.

Metal or Wooden Floor

The floor of a food-grade dry van can be made of either wood or metal.

Some people believe that a food-grade dry van trailer made from metal should be the standard.

One reason is that the metal floor is easier to clean, plus it isn’t as inviting to potential pests. Have you dealt with cleaning with metal and wood? Metal is easier to clean, and it doesn’t become moldy if left wet.

The metal used in food-grade dry van trailers is usually stainless steel. This metal material has strong corrosion resistance, which is best. You won’t need to worry about replacing your trailer’s floor anytime soon.

The disadvantage of metal floors is that it is much harder to secure pallets to prevent damage while the truck is in transit.

Additionally, wooden floors are also more likely to wear out sooner and need to be replaced in less time. Wooden floors are also likely to absorb food smells that might be hard to get out.

If your dry van trailer has a wooden floor, don’t worry. They are still acceptable for loading food items as long as there are no holes and foul smells to be found. Otherwise, there is a good chance the shipper will reject it.

Both types of floors can be used for a food-grade dry van trailer as long as there are no risks of pests and food damage.

Clean Compartment

A clean space makes a healthy environment for food items to be stored. It is also what makes a standard food-grade dry van trailer.

Germs can settle on surfaces and contaminate anything that comes in contact with them, including our hands. It is critical for food grade dry van trailer drivers to always keep all surfaces in the trailer clean.

A dirty food grade dry van trailer can breed germs, contaminating the food items loaded and make them unfit for consumption.

This is why food-grade dry van trailer operators must keep their trailers clean.

Before transporting more food items, food grade dry van trailers also have to be cleaned out after each trip.

Odorless Compartment

No foul smells are allowed in a food-grade dry van trailer.

More often than not, transporting food items can leave a trailer smelling funny unless it is thoroughly cleaned and dried.

This could be bad for hauling food items. The foul smell is likely to stay on the food items and affect their taste.

Delivery of food that is unsuitable for consumption could result in bad reviews from customers, which would be bad for the business.

The cargo could also be rejected for loading at pick-up points if any foul smell is perceived during an inspection.

To prevent this, a food-grade dry van trailer has to be odorless.

Functioning and an Easy Opening Door (Dock High)

The door of a food-grade trailer should be easy to open and close.

Unlike a reefer, a standard food-grade dry van trailer is not required to be air-tight and has many door locks.

All the same, the door locks have to be secured to avoid mishaps on the way.

In most cases, a food-grade dry van trailer is required to have swing doors instead of a roll-up door, because two doors are easier to open and close.

Nonetheless, both types of doors are acceptable as long as they are dock high and easy for warehouses to access for loading and unloading.

Controlled Temperature

Food-grade dry vans can have refrigerated trailers. These are preferred, especially for hauling food items, because the temperature can be controlled.

If you plan to haul frozen food items on your trip, refrigerated trailers are best. Even for non-frozen food, a refrigerated trailer can come in handy.

If you want your own food-grade dry van trailer, we can help you make your own. Here are tips on how to upgrade your regular dry van to a food-grade dry van trailer.

What Upgrades Should I Make to Haul Food-Grade Products?

The following are factors to consider to upgrade your regular dry van into a food-grade dry van trailer.

1. Lift Gate

Some dry vans already have lift gates that are very useful for food-grade dry van trailers.

Using a lift gate to aid loading and unloading could help avoid food spillage, damage and help make the process easier and more accessible for different warehouse locations.

2. Make Sure That Your Trailer Is in Good Shape

Food hauling is very sensitive. Food-grade dry van trailers must strictly adhere to sanitary standards. Remember, you are handling food and health care items.

You can check for holes, and keep the roof, floor, and sides smooth as possible.

3. Add a Metal Roof

If your dry van trailer already has a metal roof, that’s great! A food-grade dry van trailer requires a metal roof for durability.

It can be made from either aluminum or stainless steel to avoid corrosion.

4. Keep It Maintained

Operating a food-grade dry van trailer requires regular maintenance.

During loading and unloading of food items, food particles are likely to drop to the floor and leave it messy.

The mess can attract crawling insects, rendering the trailer unfit to transport more food items until sterilized.

By sweeping and washing, you can avoid contamination. This will help clean out hidden food particles and keep the trailer clean and neat.

5. Air Out After Delivery

The smell of food items is likely to remain in a food-grade trailer, especially after long hours of being in an enclosed space.

With time the smell can develop into an unpleasant one. This means airing out a food-grade dry van trailer is vital.

Conclusion

One of the best investments you can make in your trucking business is a food-grade dry van, protecting both your cargo and yourself. If you want to upgrade from a standard trailer to an enclosed unit that meets FDA guidelines for transporting items like fresh produce or seafood, then it’s worth investing in this type of vehicle.

These trucks are designed with special seals around their doors, so there's no chance any contamination will leak out while they're on the road. For many drivers, adding these features means working longer hours without worrying about getting sick themselves or making customers ill when delivering goods.

As such, if upgrading sounds appealing (or at least less daunting), leave us a comment below! We'll be happy to provide more information.