An ISO container is made of stainless steel with a body strengthened with various protective layers. It also uses many outer designs and different skins. The particular design used will be based on the fluid type it carries.

An ISO tank is a container built to follow the standards of the ISO or the International Organization for Standardization. These tanks function to carry bulk liquids. They transfer both hazardous and non-hazardous fluids to distant locations.

This portable tank’s reliability directly reflects its ISO label. If your business transports fluids in massive quantities, an ISO tank is your best helper. Continue reading for more information about this container.

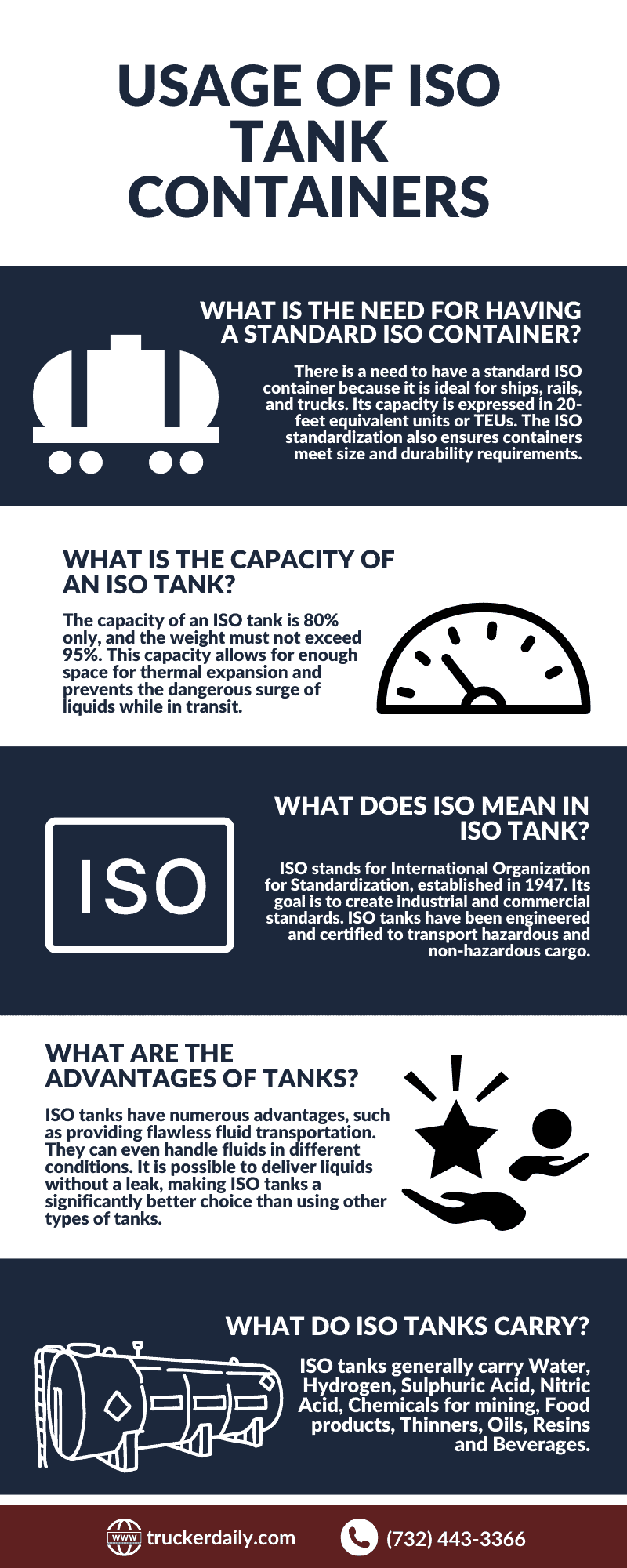

What Is the Need for Having a Standard ISO Container?

There is a need to have a standard ISO container because it is ideal for ships, rails, and trucks. Its capacity is expressed in 20-feet equivalent units or TEUs. The ISO standardization also ensures containers meet size and durability requirements.

An ISO certification guarantees the container will withstand extreme environments. It means the tank has structural integrity whether it travels over land or sea. Also, the ISO standardization allows these tanks to stack safely and uniformly on larger vessels such as ships and trains.

It is crucial to inspect ISO containers every 30 months. A certified expert checks these containers and verifies that they are within specifications.

What Is the Capacity of an ISO Tank?

The capacity of an ISO tank is 80% only, and the weight must not exceed 95%. This capacity allows for enough space for thermal expansion and prevents the dangerous surge of liquids while in transit.

Roughly 95% of containers are built to 20 feet specification. Other sizes are also available, such as 10 feet, 30 feet, and 45 feet containers. The ISO limits these containers to be shipped using intermodal shipping.

Options include container ships, rail lines, and trucks. This agility provides a safe and cost-effective way to transport cargoes.

What is an ISO Tank Container? https://t.co/KhmQhR8Nvu pic.twitter.com/GIAWhiosYQ

— TheEazyCadet (@EazyCadet) September 18, 2020

What Does ISO Mean in ISO Tank?

ISO stands for International Organization for Standardization, established in 1947. Its goal is to create industrial and commercial standards. ISO tanks have been engineered and certified to transport hazardous and non-hazardous cargo.

ISO containers transport bulk liquids. They function as shipping containers that can be transported internationally. This means they must be certified to international safety and performance metrics.

ISO tanks can reduce shipping and handling costs. These tanks allow smaller shiploads or truckloads of liquids to be packaged. These loads can be easily carried by truck to the railways and from trains to shipping decks.

In some cases, the tanks will be sent by air. These containers are all of the same sizes, with rigid mechanical frames around them with standard connections. They can be locked securely.

You can build space and other material handling devices to connect to the tanks quickly. You can securely move them, too, from vehicle to vehicle—all these results in an extra layer of safety for workers.

What Are the Advantages of Tanks?

ISO tanks have numerous advantages, such as providing flawless fluid transportation. They can even handle fluids in different conditions. It is possible to deliver liquids without a leak, making ISO tanks a significantly better choice than using other types of tanks.

In particular, the following are some of the advantages of ISO tanks:

Carry Various Types of Fluids

ISO tanks fill a specific criterion. They carry the fluids successfully they were engineered for and must not damage the tank. These mighty containers also carry fluids for long-distance travel.

Leak-Proof Transport of Fluids

ISO tanks are leak-proof, which benefits businesses that want to transport their fluids around the globe.

Can Handle High Pressure

ISO tanks containers can withstand extreme pressure, eliminating the chances of damage to the tank and fluids.

Eliminate the Need for Additional Packaging

These tanks do not need other packaging materials for the shipment. The ISO tank can be directly filled with fluid for transport and then hit the road.

Sustain the Temperature of Fluids

Robust ISO containers can carry fluids that must be kept at a specific temperature. ISO tanks can keep them at a certain temperature no matter the conditions outside. They remain unaffected by rough roads, snow, heat, and rain.

Provide the Safest Way to Transport Liquids in Bulk

These tanks were engineered to the standards of ISO. It is crucial to consider the safety of these tanks as well. They are made up of various closures and valves. It is only when these closures have failed that a leak occurs.

This means the ISO tank is the safest way to transport rare and premium liquids. If you want to drive these tanks, you must take note of truck driver duties and responsibilities. Driving a truck with an ISO tank also has several requirements for truck drivers.

Now that we’ve discussed the flawless advantages of ISO Tank containers let’s look at e the types of liquids transported in ISO Tank containers.

Something about IBC & ISO Tank: The IBC or Intermediate Bulk Container is lightweight, durable, and corrosion resistant for your liquid handling needs. An ISO Tank is a tank container which is built to the ISO standard. They are designed to carry liquids in bulk. #IBC #ISOTANK pic.twitter.com/RbTM4YbLJh

— Landmark (@NmkCinnamicAcid) July 6, 2020

What Do ISO Tanks Carry?

ISO tanks generally carry the following:

- Water

- Hydrogen

- Sulphuric Acid

- Nitric Acid

- Chemicals for mining

- Food products

- Thinners

- Oils

- Resins

- Beverages

If these tanks were to carry a solid, container longevity would become a challenge. In some instances, solids are propelled into the container as a high-temperature liquid.

How Do You Fill an ISO Tank?

Here are a few ways to fill an ISO tank:

Gravity Loading

The cargo is loaded into the tank from any overhead storage using a manhole cover. In a closed-loop system, the container must be loaded at the top or bottom outlets. The vapors will be returned to the supply tank through the airline connection.

Pressure Loading

The cargo is pumped into the tank either through the manhole cover or the top and bottom connection. In a closed-loop system, vapors are emitted back to the container through the airline.

Overall, it is vital to note that tanks must only cater to less than 80% of their capacity. Doing so can mitigate dangerous surges or swells during transport.

As we stated earlier, you should not fill your tanks beyond 100% of their capacity. There must be enough space left. Space is determined based on the thermal expansion of the cargo being transported.

You may only carry hazardous products in tanks with no openings below the surface level of the liquid. The product is discharged via a siphon pipe by either pressure or pumping.

Conclusion

ISO tanks make transportation of liquids safer and make the conveyance of any liquid leak-proof. It is the case whether travel occurs on land, sea, or air. Businesses that revolve around liquid transportation must get these robust cylinders.