A lot of things can go wrong when it comes to logistics and transportation. Most problems lie in cutting costs and managing materials. This is why there is now debate centered around the use of ISO tanks. These are used as the primary method of liquid cargo carrying, but there are advantages and disadvantages of using ISO tanks.

The many advantages of ISO tanks include safety, minimal leakage and its versatility to carry a lot of different liquids. Although cleaning an ISO tank can be costly, the benefits of using it definitely outweighs its drawbacks.

For decades, ISO tanks have proven to be the standard in bulk liquid transportation. But this doesn’t mean that there are no downsides to them.

Understanding the advantages and disadvantages of ISO tanks is important. This will make transportation choices easier and more accurate.

But that’s not all there is to know about ISO tanks. I’ll share with you everything I learned about these famous containers during the past 15 years of working in the trucking industry, so read on.

@smcglobal invests in an ISO tank fleet to ensure continuity

To view article please click here: https://t.co/JNV3te7CD9#tanknewsinternational #logistics #news #tankstorage #storageterminals #tankterminals #website #tanknews #international pic.twitter.com/A1BELxpGmJ

— Tank News Int. (@TankNewsInt) August 16, 2021

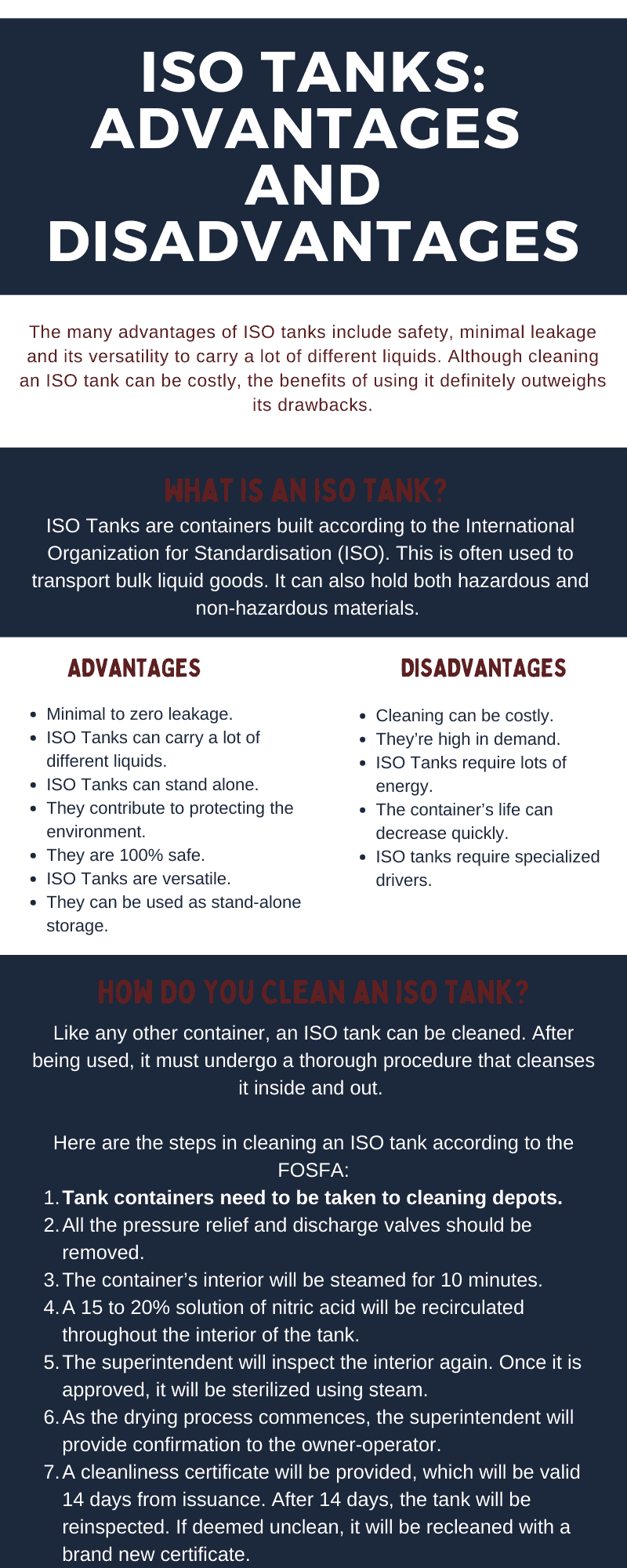

What is an ISO Tank?

ISO Tanks are containers built according to the International Organization for Standardisation (ISO). This is often used to transport bulk liquid goods. It can also hold both hazardous and non-hazardous materials.

These are the bulk liquids an ISO Tank can transport:

- Alcoholic beverages

- Any type of water

- Food-grade liquids

- Chemicals

- Mineral oils

These containers are made of stainless steel with extra protective layers. The extra layers may differ from the liquid the tank is designated to carry. Along with that, there are plenty of designs for these tanks as well.

They are considered reliable and the standard in transporting bulk liquids. This is because they are not only ISO-certified but founded on them as well. Owner-operators can rely on ISO tanks for the transportation of large liquid quantities.

What are the advantages of ISO tanks in trucking?

There are many advantages that come with using ISO Tanks in transportation. Not only that, but they have proven to be one of the best in storing various fluids and withstanding the test of time. But what else is there to ISO Tanks?

- Minimal to zero leakage.

ISO Tanks are incredibly leakproof. Because of the way they’re built, even rocky roads can’t mess with the durability of an ISO Tank. People often opt for these when delivering bulk liquids from state to state.

- ISO Tanks can carry a lot of different liquids.

They are built to carry and withstand the composition of various fluids. An ISO Tank can last for years if it doesn’t get any dents or cracks. This is why they’re ideal for long-distance transportation.

- ISO Tanks can stand alone.

The fluid to be transported doesn’t need any more packaging. It can be pumped into the ISO Tank and be ready to go. ISO tanks are also highly capable of standing against extreme pressure. This is due to the durability and efficiency of the containers.

- They contribute to protecting the environment.

ISO tanks are very strong when no cracks and dents are present. Storing the liquids in the containers prevents leakages. This can reduce the likelihood of oil and chemical leaks, minimizing environmental pollution.

- They are 100% safe.

Since the ISO are in the names of these containers, they’re considered high-quality. ISO Tanks function well and are safe to use. The protective layers and stainless steel exterior makes it durable. This is why it is the most ideal way to transport any type of liquid.

- ISO Tanks are versatile.

ISO tanks can be used over the road or in intermodal transport on railroads and ships for overseas transportation.

- They can be used as stand-alone storage.

Due to their mobility, an ISO tank can be used as a backup storage solution that manufacturers can use to hold extra product.

What are the disadvantages of using ISO containers?

Like any other method of containment, there are some downsides to ISO tanks. There are some areas where ISO tanks aren’t able to perform as well as they do. Sometimes, these are because of entirely different things.

- Cleaning can be costly.

ISO tanks are very reusable. But cleaning them can be a bit difficult. They can only be cleaned at approved facilities. This is the primary reason why cleaning an ISO tank can be expensive, whether you own one, drive one, or are looking to use one for shipment.

- They’re high in demand.

Sometimes, the supply chain can get packed up. In this case, ISO Tanks can lack availability, especially during the busiest times. There can be waiting times that go as long as weeks to months before an ISO tank becomes available.

- ISO Tanks require lots of energy.

ISO Tanks can be sustainable and eco-friendly. But the production of an ISO tank requires a large amount of energy. The process is very straining on the environment, negating most benefits of its reusability. Replacing them can be very costly too.

- The container’s life can decrease quickly.

If you use an ISO tank to carry a solid, it can be highly damaged. Some liquids are pumped as high-temperature liquids which can solidify during transportation. The process is assisted by pressurizing the tank with air. These techniques place unnecessary strain on the interior, causing cracks and dents.

- ISO tanks require specialized drivers.

The drivers assigned to haul ISO tanks are usually in short supply. Hauling ISO tanks require a special chassis paired with a tanker endorsed driver that is experienced in hauling chemical products. Since ISO tanks can be used in ports and railroads, drivers might need other credentials like TWIC cards and SCAC codes.

Some of these problems have their respective alternatives. However, they can be costly and heavy to fix. An ISO tank is worth the trouble because of its durability and flexibility. But it will still depend on the clients and the owner-operators.

Cleaning, inspection and spark testing of rubber lined ISO tanks. Offshore acid tank lining #acidtank pic.twitter.com/zmXQXdLxoA

— YRL (@YRL_Rubber) September 23, 2016

How Do You Clean an ISO Tank?

Like any other container, an ISO tank can be cleaned. After being used, it must undergo a thorough procedure that cleanses it inside and out. This ensures that the interior of the container is clean. It should be free from any residue and leftover from the previous liquid stored in it.

Here are the steps in cleaning an ISO tank according to the FOSFA:

- Tank containers need to be taken to cleaning depots. Here, the previous cago should be declared to a superintendent. It must include documents that support the declaration as evidence. The cargo must fit the standards of the FOSFA List of Acceptable Previous Cargoes.

- All the pressure relief and discharge valves should be removed. These will be cleaned, and further examined. The container will be fitted with newer gaskets.

- The container’s interior will be steamed for 10 minutes. This is followed by a detergent spin and 10 minutes of rinsing. If the depot lacks items approved for cleaning products, low caustic products can be used.

- A 15 to 20% solution of nitric acid will be recirculated throughout the interior of the tank. This will be followed by freshwater to remove traces of nitric acid.

- The superintendent will inspect the interior again. Once it is approved, it will be sterilized using steam.

- As the drying process commences, the superintendent will provide confirmation to the owner-operator. This is for the next cargo that will be loaded onto the container.

- A cleanliness certificate will be provided, which will be valid 14 days from issuance. After 14 days, the tank will be reinspected. If deemed unclean, it will be recleaned with a brand new certificate.

I have been using ISO tanks for years and I can say that the efficiency and reliability of these containers are still undefeated. Despite the requirements in cleaning and maintenance, it proves itself worth it. Transportation is an industry that continues to rise in popularity. ISO Tanks are doing their part in that growth and are vital to the economy.Sources:

ISO. International organization for Standardization. https://www.iso.org/home.html

FOSFA. FOSFA qualifications and operational procedures for ISO tank containers carrying animal, marine and vegetable oils and fats. https://www.international-tank-container.org/en/technical/fosfa