An ISO tank container is generally used for transporting and storing hazardous and non-hazardous chemicals, food, and liquified gases. Its linings help reinforce them against chemical damage, and it can withstand fluctuations in pressure and temperature. However, some might still ask if these ISO tank containers are safe.

ISO tank containers are safe because they can regulate temperature for temperature-sensitive cargo. These tank containers are reliable. Many are manufactured from stainless steel, which is corrosion-resistant. They are also eco-friendly.

Moreover, ISO tanks can be stacked, increasing the ease of handling and storage. They are also durable and have a long lifespan, leaving a minimal carbon footprint that’s 50% less than an equivalent drummed shipment. To learn more about these ISO tank containers, read on.

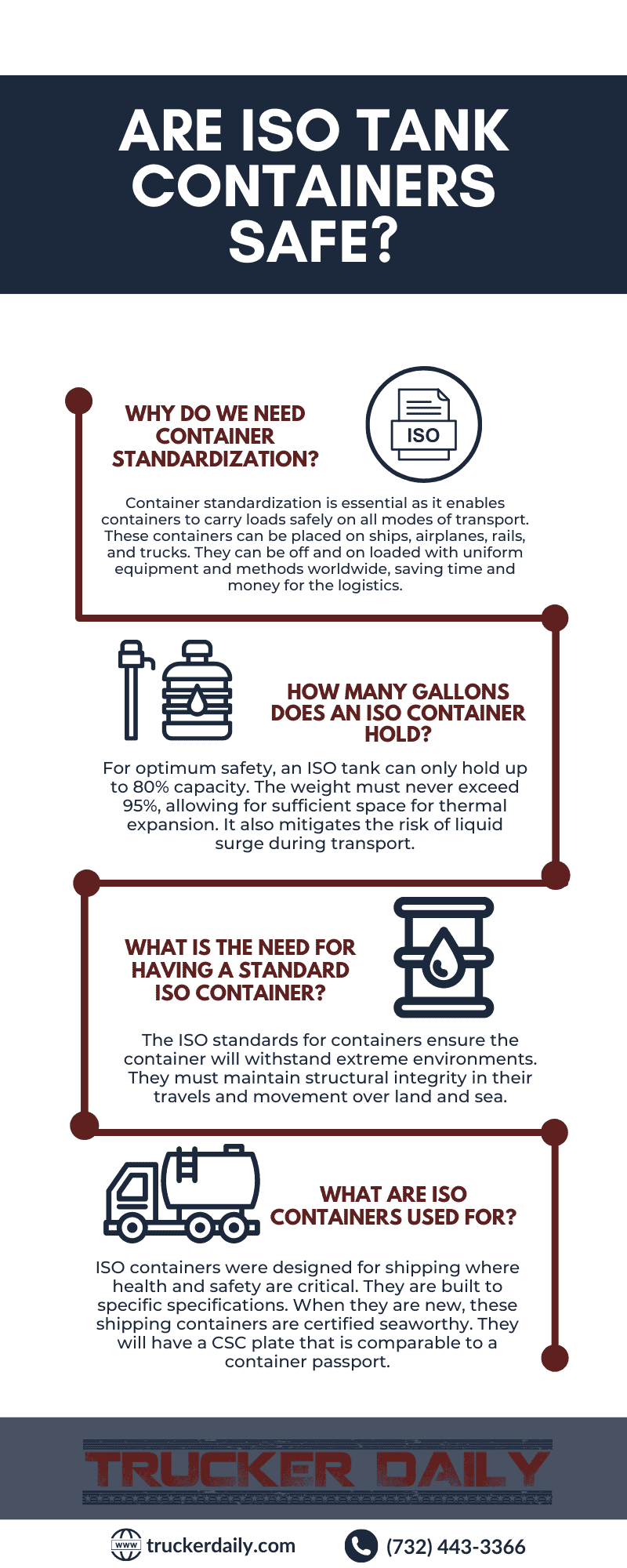

Why Do We Need Container Standardization?

Container standardization is essential as it enables containers to carry loads safely on all modes of transport. These containers can be placed on ships, airplanes, rails, and trucks. They can be off and on loaded with uniform equipment and methods worldwide, saving time and money for the logistics.

Containerization is a process of intermodal freight transport, using intermodal containers such as shipping containers and ISO containers with standardized dimensions.

You may load and unload, pile and transport these containers over long journeys. They can be transferred from one transport mode to another, placed on ships, rails, and trucks, and sealed.

Handling systems are entirely mechanized and done either by cranes or forklifts. Everything is numbered and tracked using a computer system.

The International Standards Organization has established container standards since 1968. It designated specific corner fittings and the internal size of general-purpose fight containers. At this time, standards regarding terminology, dimensions, ratings, and markings were approved. During the 1970s, further ISO standards were developed.

The fuel tank used for storage diesel, gasoline, kerosene, etc.

Dimensions as Standard ISO Container, 20ft, 40ft HQ.

Tank’s capacity from 1000 to 10000Liters pic.twitter.com/P3Z07CmNcj

— LING (@LING04571317) May 23, 2019

How Many Gallons Does an ISO Container Hold?

For optimum safety, an ISO tank can only hold up to 80% capacity. The weight must never exceed 95%, allowing for sufficient space for thermal expansion. It also mitigates the risk of liquid surge during transport.

Roughly 95% of containers are engineered to 20 feet specifications. However, they also come in other sizes, such as 10 feet up to 45 feet. The ISO limits the use of these containers to intermodal shipping.

They can be transported using container ships, rail lines, and trucks. This ability allows for a safe and cost-effective way to transport goods.

What Is the Need for Having a Standard ISO Container?

There is the need for ISO standards for containers to ensure the container will withstand extreme environments. They must maintain structural integrity in their travels and movement over land and sea.

The following are the standards of ISO for tanks:

Dimensions and Ratings

This standard is the most crucial. It provides information on the container’s dimensions, and will include the positioning of the corner fittings.

Corner Fittings Specifications

This standard is also critical as it focuses on the dimensions of the tank. It factors in the container’s parts and their mechanical resistance.

Handling and Securing

This standard defines acceptable practices for the lifting of containers. It also factors in lashing on board. It focuses on how containers will be transported on sea and land. This standard is critical given the growth in the size of container ships.

Truck drivers must have special knowledge when carrying these tanks.

You must know the requirements for truck drivers when carrying ISO container tanks.

General Communication Codes

This standard provides all information concerning codes. These codes are used to communicate between various transport points. These include ports, depots, repair shops, and many others.

What Are the Advantages of Container Transport?

Here are some of the advantages of container transport:

Standardization

The container is a standard transport product, which you can handle in any part of the world through specialized modes. These modes include ships, trucks, barges, and wagons.

Every container has a specific identification number and code. A container is a special transport unit that can be managed as such.

Flexibility

You can use these containers to carry a wide array of goods and commodities. These include wheat, manufactured goods, cars, and perishable goods. There are special containers for dry cargo liquids and refrigerated cargo as well. Old containers can be recycled and refurbished for other purposes.

Cost Savings

Container transportation has lower transport costs. Moving a uniform amount of break-bulk cargo in a container is less expensive. It is more affordable than ordinary means. Containers enable cost advantages at terminals that were impossible via standard break-bulk handling. The primary benefit of containerization comes from lower intermodal transport cost.

Speed

Operations of transshipment are nominal and swift. The ship port turnaround times have been lessened from several weeks to one day. Because of this advantage, transport chains involving containers move faster. Shipping networks are well-connected and provide wide-ranging shipping options. Container ships are also quicker than regular cargo ships.

Warehousing

The container serves as its warehouse. It protects the cargo, so there is more straightforward and less expensive packaging for containerized freight. It is especially the case for consumption goods. The piling capacity on ships and trains is a benefit of containerization. With the right equipment, a container yard can increase its stacking ability.

Security and Safety

The contents of an ISO container are usually unknown to carriers. It can only be opened at the origin point, at customs, and the destination. This reduces spoilage and losses from theft.

Truck drivers who plan on carrying these tanks must have specialized skills.

You must check out truck driver duties and responsibilities for ISO container tanks.

Crowley Loads 1st LNG into ISO Tank Container at Eagle LNG Partners’ New Plant https://t.co/nGWDg4xaAq pic.twitter.com/8bjGMBoUhA

— Sea News (@SeaNews11) March 29, 2018

What Are ISO Containers Used For?

ISO containers were designed for shipping where health and safety are critical. They are built to specific specifications. When they are new, these shipping containers are certified seaworthy. They will have a CSC plate that is comparable to a container passport.

Overall, ISO tanks in transit are at the temperature of their surroundings. Some tanks will have heating and cooling to run electrically while on the ship or truck.

This is similar to the refrigerated over-the-road truck trailers that transport food and dairy. In these cases, the carriage must provide electricity. It must be able to control the temperatures of the ISO tank.

But ISO tanks are also vulnerable to some risks. These include accidents in transit, loading or unloading, and fluctuations in temperature. The pressure inside it can also cause the shell of the tank to get stressed.

Common damage to the coating of an ISO tank is breaking and chipping. It happens when working around or in the tank with tools and massive hose connections.

Any metal that touches corrosives will start breaking down. If the protective coating is compromised, the exposed metal can break the bond of the layer.

Some of the protective coatings can be repaired on the field. Technicians can clean and replace the areas broken off to restore the tank’s integrity. However, some coatings will need complete blasting of the vessel and a recoat.

Conclusion

ISO tanks follow standardization procedures, which makes them safe and effective modes of transport. They can carry massive amounts of goods securely. These tank containers are built from steel and engineered to last for the long term.